High-Density Aeration Designs in Sewage Plants – An Essential Consideration

March 23, 2021

Sewage treatment plants in Australia consume some 1000 GWh per annum of electricity. In general, the energy demand is between 20 – 50 kWh per person per year.

Whilst the energy consumption of a sewage plant depends on the process – in general half of the power demand is used to drive the aeration process within the secondary treatment process.

Optimising the aeration system is key to reducing the sewage treatment plant’s energy consumption and carbon footprint. An efficient aeration system can save 30% or more power and associated carbon emissions.

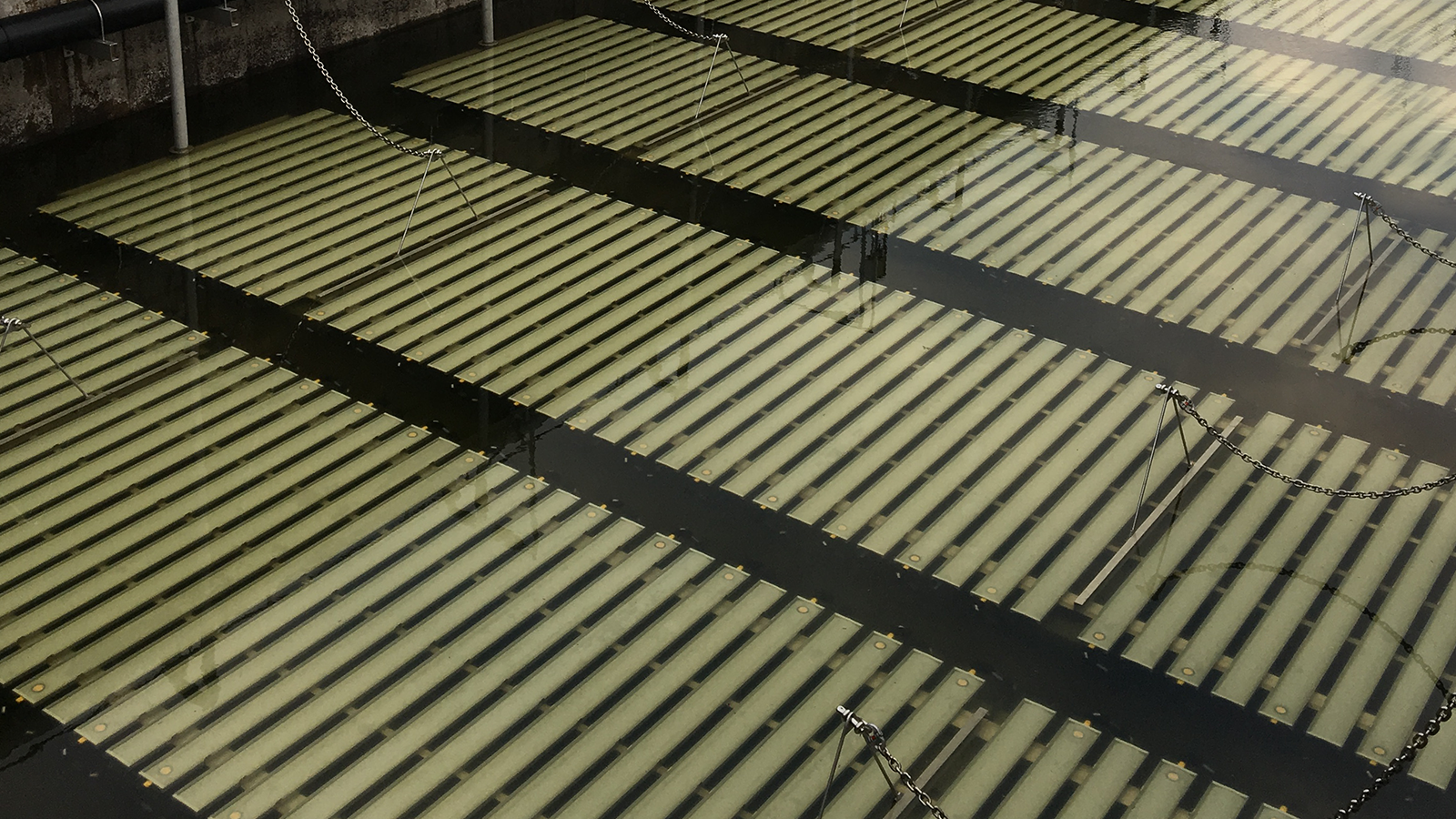

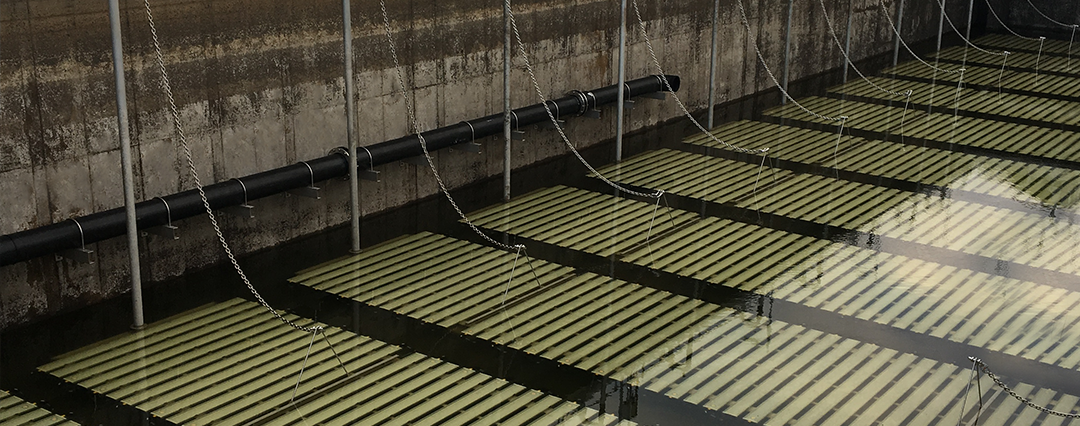

Sewage plant owners and operators should also consider the use of high-density layouts in addition to selecting high efficiency diffusers. Moving to a higher density reduces diffuser flux rates which increases energy efficiency as less air is required for the same net oxygen yield.

For example, AEROSTRIP® fine bubble diffusers can be arranged in grids that provide up to 90% floor coverage, however in practice moving from a floor density of say 12% to 25% can result in an additional 15 – 30% energy reduction.

Hydroflux Epco’s modeling software can quickly compare ‘like for like’ floor density against higher density layouts. This allows clients to understand the power and OPEX savings against increased CAPEX (ie Total Cost of Ownership).

Contact us on www.hydrofluxepco.com.au for further details.

Want to stay up-to-date with what is going on? Click Here to follow our Page for the latest updates.

Up Next

Cleaning of Polymer Spills Has Never Been Easier

Wells for World Water Day 2021

Categories

- Tradeshows

- Climate

- Community Engagement

- Corporate Announcements

- Group News

- Newsletters

- Product News

- Project Announcement